Cooling System-Fan And Wind Scooperon Selection

1.Suction and exhaust fans: For equipment with higher speed, when the engine is installed in the front part of the equipment, the suction fan can be selected to make good use of the oncoming wind to enhance the cooling effect; when the engine is installed at the back end, generally choose the exhaust fan.

For equipment with low walking speed, you can choose suction fan or exhaust fan. In general, because the suction fan uses cooler air to cool the radiator, The efficiency is significantly higher than the exhaust fan.

2.Fan speed and diameter: With the same power consumption, the cooling effect and noise of low-speed and large fans are obviously better than that of high-speed and small fans. In addition, when choosing a fan, pay attention to the tip speed of the fan should not exceed 4200~5000 m/min.

3.Distance between fan and radiator core: suction more than 2 inches, exhaust more than 4 inches.

4.Distance between fan and engine: should be as far as possible if fan support the bending moment (7 NM) permits, but fan pad thickness is generally not allowed to exceed 3 inches.

5.It is forbidden to use elastic loosening washers when instal the fan to prevent damage to the fan flange due to concentrated stress.

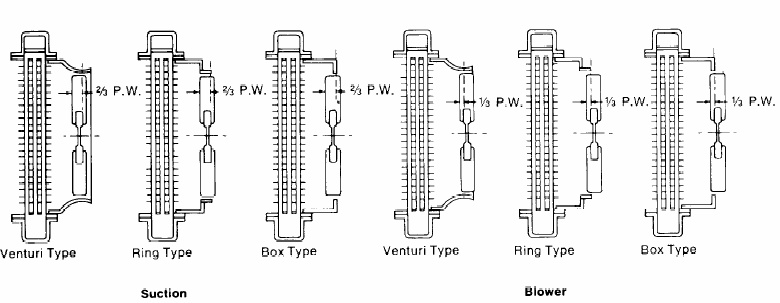

There are three commonly used wind scooper types: box, ring , and throat type , see the figure below.

1.The wind scooper and radiator must be sealed.

2.The gap between the fan tip and the wind scooper is generally 1.5~2.5% of the fan diameter;

3.Fan position in the wind scooper: suction,2/3 in, exhaust, 1/3 in.