How to Fix Serpentine Belt Noise

The Real Reason Belts Squeal,Chirp and Make Other Noise

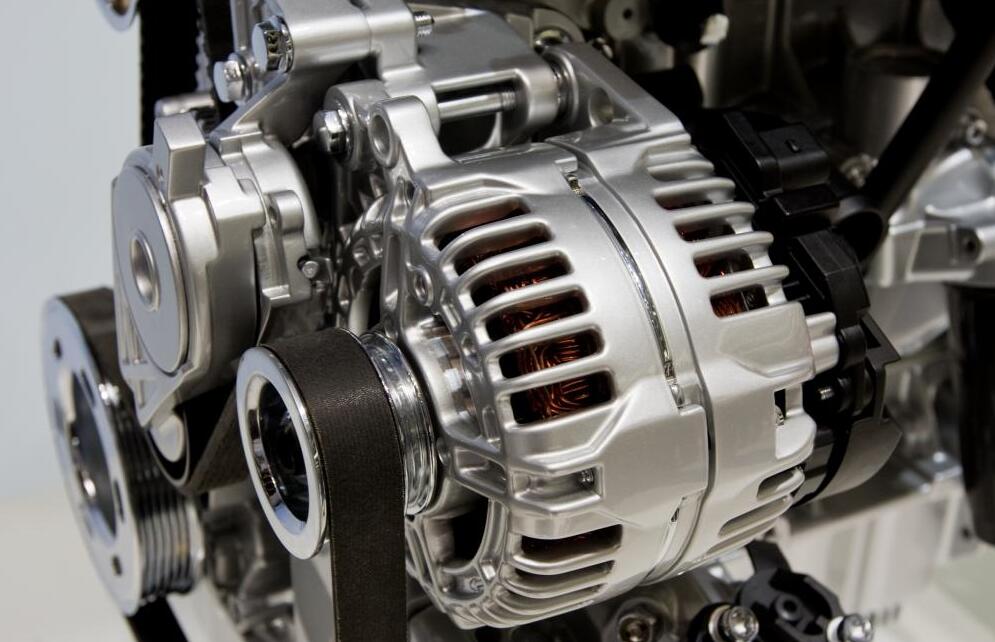

If the newly installed serpentine belt makes noise, it indicates that there is a problem with the front end drive system of the engine. The serpentine belt noise is equivalent to the "check engine" indicator, indicating that there is a problem with the belt drive system. But surprisingly, belts are often not the culprit.

Squeak and chirp: the most common snake-like noise

The serpentine belt usually makes two kinds of noises. One is twittering, the other is screaming. They are the result of different problems in the front-end drive system.

Serpentine belt chirp

Chirp made a series of sharp and intermittent "rhythmic" sounds. As the belt speed increases, the pitch and volume remain unchanged, so continuous belt chirp will be heard during acceleration.

Six causes of chirp

1.Belt pulley misalignment, the number one cause of noise

2.Improper installation

3.Belt rib wear

4.The pulley bearing is worn, causing swing or excessive free swing

5.Contamination of oil, power steering fluid, antifreeze or belt dressing

6.Low quality belt installed

Solution of dislocation chirp

1.Use a ruler or laser alignment tool to check the alignment of all pulleys.

2.Ensure that all accessory pulleys and brackets are fastened to their mounting surfaces.

3.Check and replace all accessories and pulleys that are difficult to rotate due to rough or jammed bearings, or swing or loosen excessively. Remember that power steering pulleys and worn harmonic balancers can also cause misalignment.

Snake belt squeak

The scream is very high and lasts for several seconds. The volume may change, but the tone will not change.

Three main reasons for squeaking

1.Low belt tension may be caused by low installation tension, belt tension, serious belt wear, deterioration of tension spring or long belt.

2.The resistance of the accessory/idler gear is large due to the stuck bearing or the failure/locking of the accessory.

3.Liquid contamination on the belt due to contact with belt dressing, oil, antifreeze or other chemicals.

Solution to tension squeak

1.Check whether the tension applied by manual tensioning is appropriate (35 pounds per rib), and then re-tension (30 pounds per rib) after 5 minutes of trial operation. This allows the belt to be fixed in the pulley.

2.On vehicles equipped with automatic belt tensioner, the tensioner pulley shall be able to rotate freely without restraint, and the tensioning arm shall move smoothly with sufficient tension within its entire range of motion.

3.Always check the tensioner bearing for noise and wear. If the bearing feels rough or the pulley jumps, replace any tensioner.

4.When removing the belt, check all accessory pulleys and idlers to ensure free and smooth rotation. If the bearing gets stuck or rotates unevenly due to drying, replace the pulley and/or accessories.

5.If the belt is contaminated by oil, power steering fluid, antifreeze or any other petroleum-based lubricant, it will weaken or even cause the EPDM belt to expand and generate noise. Any oiled serpentine belt must be replaced.

6.Don't try to solve the problem of belt trimming.