Structural features of tractor rear axle

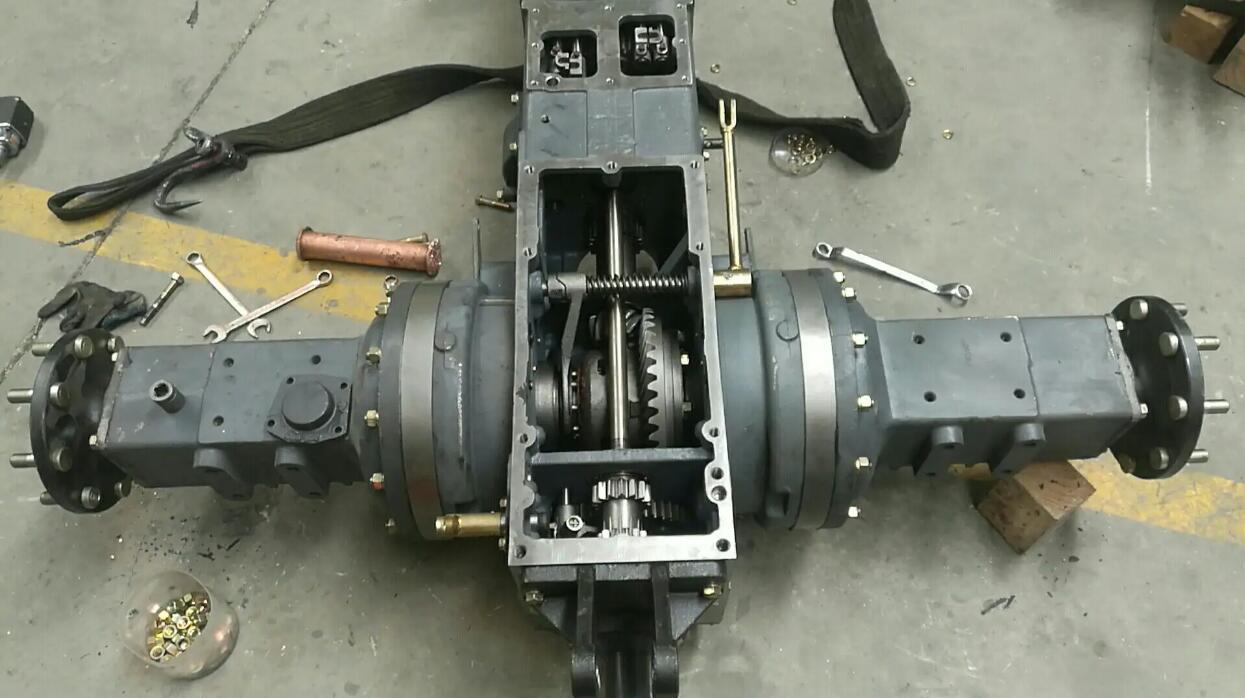

The rear axle of the tractor, also known as the drive axle, is the general name of all transmission mechanisms behind the transmission and before the drive wheel. The function of the rear axle is to distribute the power input from the transmission to the left and right drive wheels after reducing the speed and increasing the torque and changing the power transmission direction, so as to drive the tractor and allow the left and right drive wheels to rotate at different speeds. The rear axle of a wheeled tractor consists of a central drive, a differential, and a final drive. In order to meet different use requirements, there are two basic types of rear axle arrangement of wheeled tractor, the external type of final drive and the internal type of final drive. The external type of final drive arranges two final drive devices close to the driving wheel and has a separate housing; For the built-in final drive, the two final drives are arranged in the same housing near the central drive and the differential. The rear axle of crawler tractor is composed of central transmission, steering mechanism and final transmission. The central transmission and steering mechanism are arranged in the same housing, while the final transmission is arranged in separate housings on both sides.

Structural features

(1) Central drive. Because the load of the central transmission is many times larger than that of the gearbox, the central transmission gear has a higher bearing capacity. Except for the cylindrical gear pair used for small tractors, all of them are bevel gear pairs. Its basic function is to reduce speed and increase torque, and change the direction of torque transmission. Bevel gears can be divided into straight teeth, spiral teeth and hyperboloid teeth according to the shape of tooth surface pitch line. Spiral gear has compact structure, large bearing capacity, stable operation and low noise.

(2) Differential and differential lock. The function of the differential is to make the two drive wheels rotate at different speeds when the tractor turns, so as to facilitate steering and avoid damage to tires and other parts due to wheel sliding. In addition, it can equally distribute the torque of the central drive to the left and right axle gears. When the tractor runs in a straight line, the resistance moment acting on the two drive wheels is basically the same, then the planetary gear does not rotate around the planetary gear shaft, that is, it does not rotate itself, and drives the left and right half axle gears to rotate at the same speed, at this time, the differential does not work; When the vehicle turns, the steering torque makes the resistance of the inner drive wheel of the tractor greater than the resistance of the outer drive wheel, making the force of the left and right half shafts on the planetary gear unequal, and the planetary gear rotates automatically, making the inner speed lower, and the outer speed higher, so as to achieve smooth steering. If one side of the wheel is braked, the half axle gear on that side stops rotating, while the half axle gear on the other side rotates at double speed, making the tractor spin in place.

Although the differential can make the tractor turn smoothly, it greatly reduces the passing ability of the vehicle on the muddy and slippery road. Once one side of the drive wheel slips, the other side of the wheel will not get the driving force and cause the vehicle to sink. Therefore, many wheeled tractors are equipped with a differential lock. By manipulating the handle on the right side of the driver's seat, the left and right half shafts of the differential are connected, the differential effect is lost, and the driving force is obtained. The driving wheel on the non-slip road side is used to drive out of the car sinking section. Once driving out, the differential lock handle should be loosened, and the differential effect should be restored, so as to avoid steering difficulties, or even damage to the differential or cause accidents.

There are several basic types of final drive arrangement

Transmission type 1

Diesel engine--clutch--gearbox--rear axle--drive wheel

Transmission type 2

Diesel engine--double-acting clutch (main)--gearbox--rear axle--drive wheel

(3) Final drive. The final drive is the last reduction mechanism in the tractor transmission system. Its main task is to further increase the torque and reduce the speed after the central drive. The transmission ratio of the final drive is generally large, and a pair of straight cylindrical gears (also planetary gear transmission) are widely used. The left and right final drive pinions are connected with the left and right half shafts, which are supported by bearings and installed in the left and right half shaft sleeves respectively. The reducer driven gear is connected with the drive wheel shaft by splines. The drive wheel shaft is supported in the final drive housing by two tapered roller bearings. The extended end of the shaft is provided with a drive wheel adapter for installing the drive wheel. The inner ring of the two tapered roller bearings is clamped by the spacer sleeve on the shaft and the nut at the inner end of the shaft, and the outer ring is held by the bearing caps at both ends, and the bearing clearance can be adjusted by the adjusting shim under the inner bearing cap. Self-tightening oil seal is installed in the outer bearing cover to prevent oil leakage and muddy water immersion. The final drive housing is connected to the axle shaft housing with bolts and locating pins. A self-tightening oil seal is installed between the axle shaft and the housing at the connecting part to prevent the lubricating oil in the final drive from flowing into the axle shaft housing and affecting the brake operation. The installation position of the final drive housing on the axle shaft can be changed to adjust the ground clearance of the tractor and the axle torque between the front and rear wheels. There are separate oil filler and drain ports on the housing.