How to replace filter element of oil-gas separator of air compressor

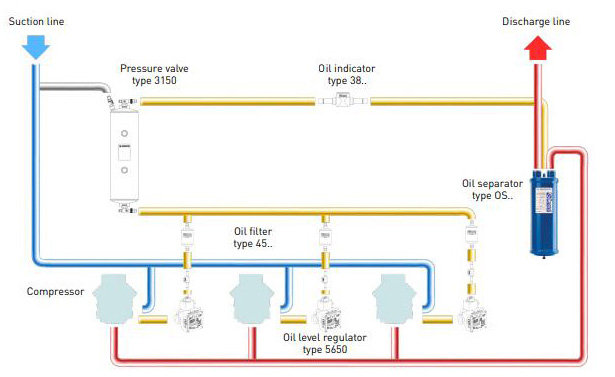

The oil leaving the compressor through the discharge port can be separated from the refrigerant and returned to the compressor crankcase by installing an oil separator.

When the lubricating oil consumption of the air compressor increases significantly, check whether the oil filter, pipeline, oil return pipe, etc. are blocked. After cleaning, if the oil consumption is still high, it may be that the oil-gas separator is aging and needs to be replaced; When the differential pressure at both ends of the filter element of the oil-gas separator reaches 0.15 MPa, it shall be replaced; When the pressure difference between the two ends is 0, it indicates that the filter element is faulty or the air flow is short circuited. At this time, replace the filter element. Generally, the replacement time is 3000~4000 hours. If the environment is harsh, the service time will be shortened accordingly.

Replacement steps:

1.External machine. First shut down the machine, then close the air pressure outlet, open the discharge valve, confirm that the system has no pressure, and replace the oil-gas separator.

2.Built in computer. First shut down the machine, then close the air pressure outlet, open the drain valve, confirm that there is no pressure in the system, remove the pipe above the oil-gas tank, remove the pipe from the outlet of the pressure retaining valve to the cooler, remove the fixing bolts and cover of the oil return pipe and the upper cover of the oil-gas tank, and finally remove and replace the oil-gas separator.

Installation:

Install in the reverse order of removal. When installing the oil return pipe, make sure that the oil return pipe is inserted into the bottom of the filter element. When replacing the oil-gas separator, pay attention to electrostatic discharge, and connect the internal metal mesh with the oil drum shell. Five or so staples can be nailed on the upper and lower pads. The staples should be nailed through to prevent static electricity accumulation and fire explosion.